The research, published in Nature, could help extend the applications of titanium alloys, improve sustainability and drive innovative materials technologies.

Titanium and titanium alloys are essential for a wide range of technologies. The research holds promise for a new class of more sustainable high-performance titanium alloys for applications in aerospace, biomedical, and chemical engineering, as well as defence, space and the clean energy transition.

The research was led by the University of Sydney and RMIT in collaboration with Melbourne company Hexagon Manufacturing Intelligence.

Co-lead researcher, University of Sydney Pro-Vice-Chancellor (Research Infrastructure) Professor Simon Ringer said: “This research delivers a new titanium alloy system capable of a wide and tunable range of mechanical properties, high manufacturability, enormous potential for emissions reduction and insights for materials design in kindred systems.”

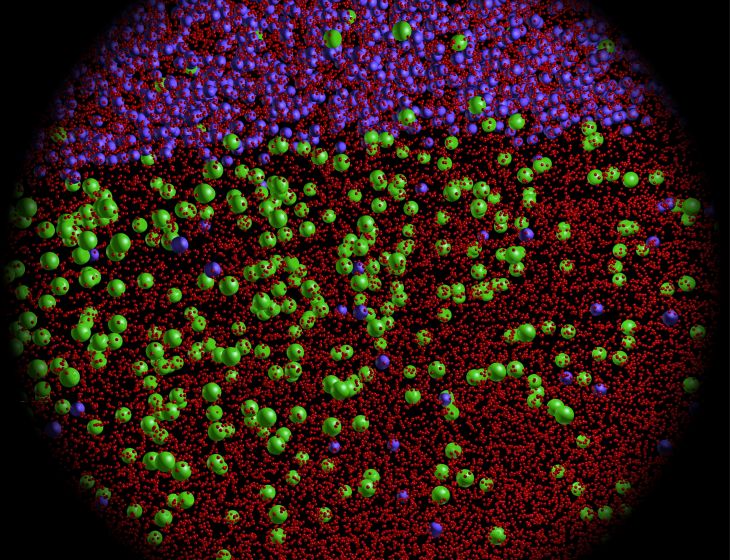

The new materials belong to an alloy class that has long been the backbone of the titanium industry. They consist of a mixture of two forms of titanium crystals, called alpha-titanium phase and beta-titanium phase, each corresponding to a specific arrangement of atoms.

While titanium alloys have traditionally been produced by adding aluminium and titanium, the researchers investigated the use of oxygen and iron – abundant and inexpensive elements that can act as powerful stabilisers and strengtheners of alpha- and beta-titanium phases.

“The critical enabler is the unique distribution of oxygen and iron atoms within and between the alpha-titanium and beta-titanium phases,” said Professor Ringer, an expert in materials science and engineering in the School of Aerospace, Mechanical and Mechatronic Engineering.